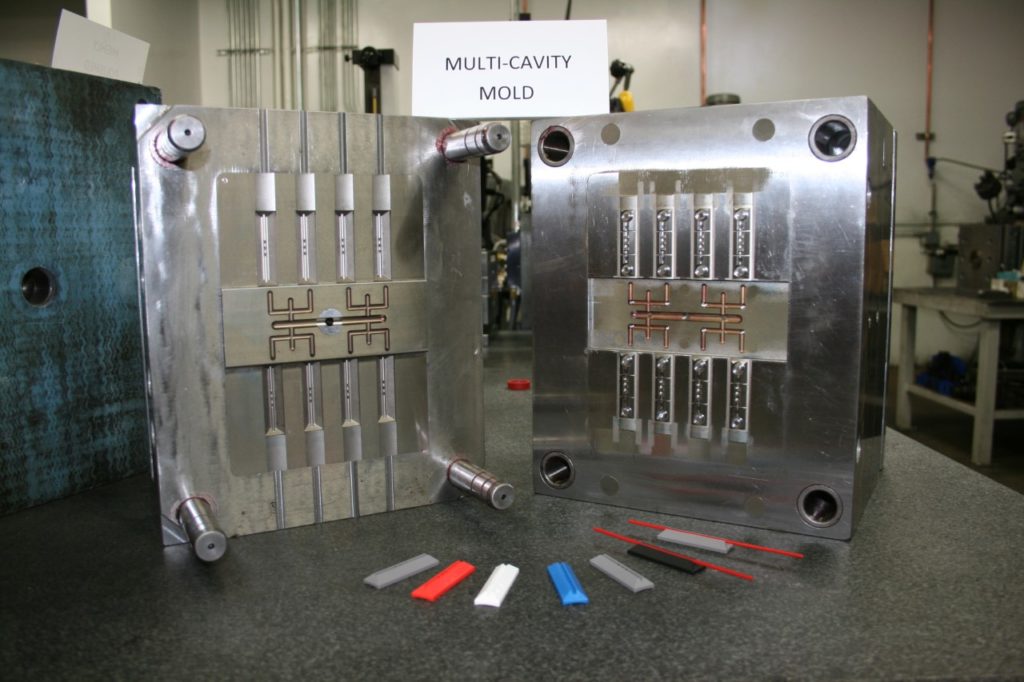

A multi-cavity mold is a a mold with multiple cavities of the same part that is typically used to reduce piece-part pricing for higher volume parts.

A multi-cavity mold is a a mold with multiple cavities of the same part that is typically used to reduce piece-part pricing for higher volume parts.

In addition to a single item being produced in a molding process, the mold can also be designed to produce multiple numbers of the same part in the same process or at the same time. A custom injection mold with a single impression is generally called a single cavity mold, and a custom injection mold with two or more cavities of the identical part is referred to as a multiple cavity mold (multi-cavity mold) or a multiple impression mold. High-volume molds, such as, bottle caps, zip ties or toothbrushes can have over 64 cavities.

A multiple cavity mold similar to a “family” mold; however, a family mold is different and is a custom injection mold that can produce multiple, similarly-sized parts in the same quantity, color and material. Family custom molded plastic parts are generally part of an assembly for a single plastic product, such as a top half and bottom half.

If you want more than tens of thousands of parts per month, then a Multi-Cavity Mold is for you. Mold Precision recommends more than a single cavity mold when the capacity is going to be greater than 40,000 pieces a month. That capacity limitation is what would generally force you to buy a multi-cavity tool. We also recommend going with a multiple cavity mold when the customer is trying to meet a certain price point. When you with multiple cavities, know that your larger upfront investment in molds & mold design is rewarded with lower piece prices. It is this reward that sometimes drives customers to purchase multi-cavity molds even when capacity isn’t reached. A multi-cavity mold could be 2, or 64 cavities or anywhere in between.

You’ll quickly find out that what you are really buying is machine time. So the less machine time it takes to mold your parts, the less your parts will cost. Unfortunately, a multi-cavity mold can grow to quite an investment as cavities are added. But the sooner you make that investment, the sooner you can reap its rewards.

When going to a multi-cavity mold, there are certain design adjustments that need to be made given various considerations. Such as, gate types & placement, balanced flow, tight tolerances, consistent venting, the pressure & speed of flow required forcing molten plastic through a mold as the molds become larger and more complex.

Click here or call 805-522-8817 to consult with Mold Precision about your project today.