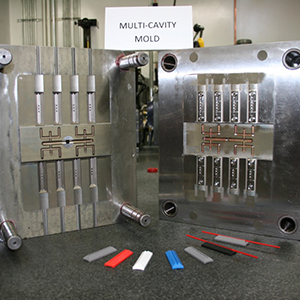

Mold Precision is proud of Flex Knit Needles’ Innovations Finalist Award at the Creativation Show

Flex Knit Needles was an innovations finalist at the - awarded by the Association of Creative Industry at the Creativation Show. Marlene Tabibian, client of Mold Precision and inventor of Flex Knit: a patented, flexible and ergonomic straight knitting needle designed to improve comfort during knitting by enabling bending with resiliency at the wrist level. Patented Ergonomic Bendable Straight Knitting Needles!